Know Everything About Crimping Dupont Connectors!

Dupont Connectors are also known as Jumper Wire Cables. They are low-cost cables available at budget-friendly rates and are employed to connect hardware of all different types, including sensors, breadboards, and Arduino boards. The connectors are available in both male and female variants of 2.54 mm pitch. The major drawback of this cable is that it is not available in any store; that said, you will have to crimp it on your own using the right components if you want to use it.

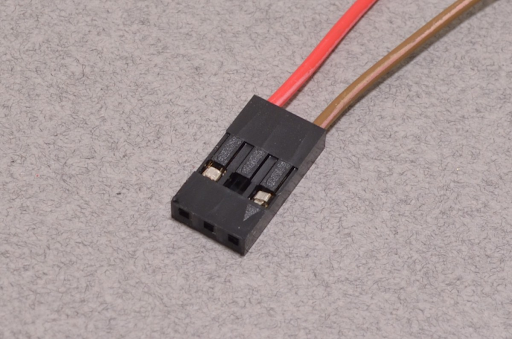

The connectors consist of sockets or metal pins that come in a plastic casing and are used to connect the individual wires to the header pins present on the PCB. You must have already seen them in your real life while connecting the speakers, the LEDs to your PC, or connecting anything to the power supply.

To crimp the Dupont connectors, you will require a proper crimping tool. The tool you will require is similar to the one you use to attach the wires to the large spades.

Pins or Socket:

The pins or sockets used in the process are available in the form of a tree, i.e., they are attached to a strip. To detach them from the strip, you can either use a cutter or rock them back and forth until they come loose.

Things to Keep in Mind While Crimping Pins

Using single core wire is not recommended at all. The arms at the center of the crimping connector should bite into one another, and the strands of the wire will then get partitioned. Doing so with a single core is very difficult, and it often goes like a hit-and-miss affair.

Another thing to keep in mind is not to tin or solder the wires with multiple strands. This ultimately converts the multiple cores into a single core, and the various problems start occurring.

The last tip, but the most critical one is as follows. You should be aware of the total thickness of the wires that you have. If you have very thick wires, then you may face issues during the process. The best way to check if your wires are too thick is by noticing if there is a need for pre-bending the connector to hold the wire.

Without further ado, let us all go through the steps of crimping Dupont connectors appropriately.

-

You will need a connector with a pair of pliers, and you will have to hold it from the front. The other end, known as the crimp of the connector, should be exposed.

-

The next step involves placing the connector into the tool with its legs facing downwards. It would help if you pushed them down enough so that the connector stays intact, in its place without the worries of getting slipped out; however, it shouldn’t be enough to begin the crimping process.

-

There will be a hole, and you will have to thread the wire through that hole. Push the wire inside enough so that you can see that a sufficient amount of the insulated part of the wire is inside the hole. If that portion of the wire does not fit in, then your wire is too thick.

-

You still need to check that the tabs placed on the connector are still facing down. Also, the tool should be pressing down on the top of the connector.

-

Then you need to press down further and crimp. With most tools, you should press the crimp down until the last click sound is heard. However, it shouldn’t be until the tool cannot be compressed further.

-

The crimping of the Dupont Connector is done, and you can check your work. The pin should be straight by now, and the crimped end of the Dupont should have taken a square-ish shape, and it will be in line with the rest of the connector. If you notice that the connector has bent too much, you can use pliers to straighten it again. Moreover, if the crimp has gone too flat, you can also squeeze it back into the original shape with the help of pliers.

More About Dupont Connectors

The Dupont connector is a vernacular term that refers to several different kinds of 0.1″ pitch connectors. They have housing of black plastic that is beneficial in retaining contacts with the help of fingers built into the housing body. All of the connectors are very similar in appearance, but they all differ in terms of price and quality.

As mentioned above, the connector is also known by other names. Different cable manufacturers know the product by different names, but they are all molded into one product.

In certain cases, the Dupont connector may refer to some of the unrelated connector types that more or less resemble the original design vaguely. However, they are all different in the sense that they have different details.

The mini PVC connectors, known as the Dupont connectors are mostly used in breadboard prototyping.

More Stories

Role of HRMS in Mobile App vs Biometric Integration for Right Attendance

HRMS Invensis: Benefits and HRMS Services Offer by Invensis

JCBL HRMS: Key Features and Benefits